Chemical Plant

Problem

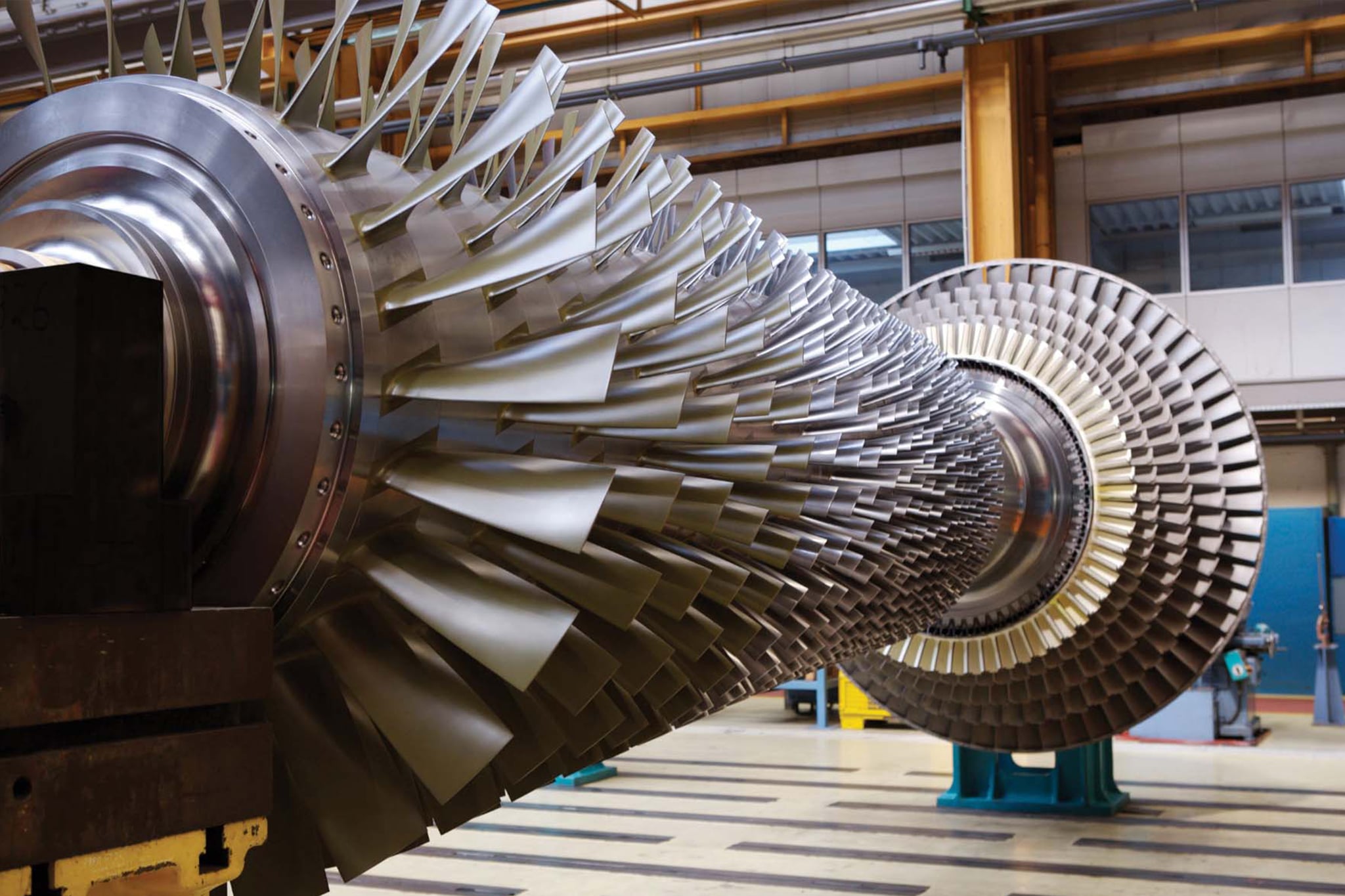

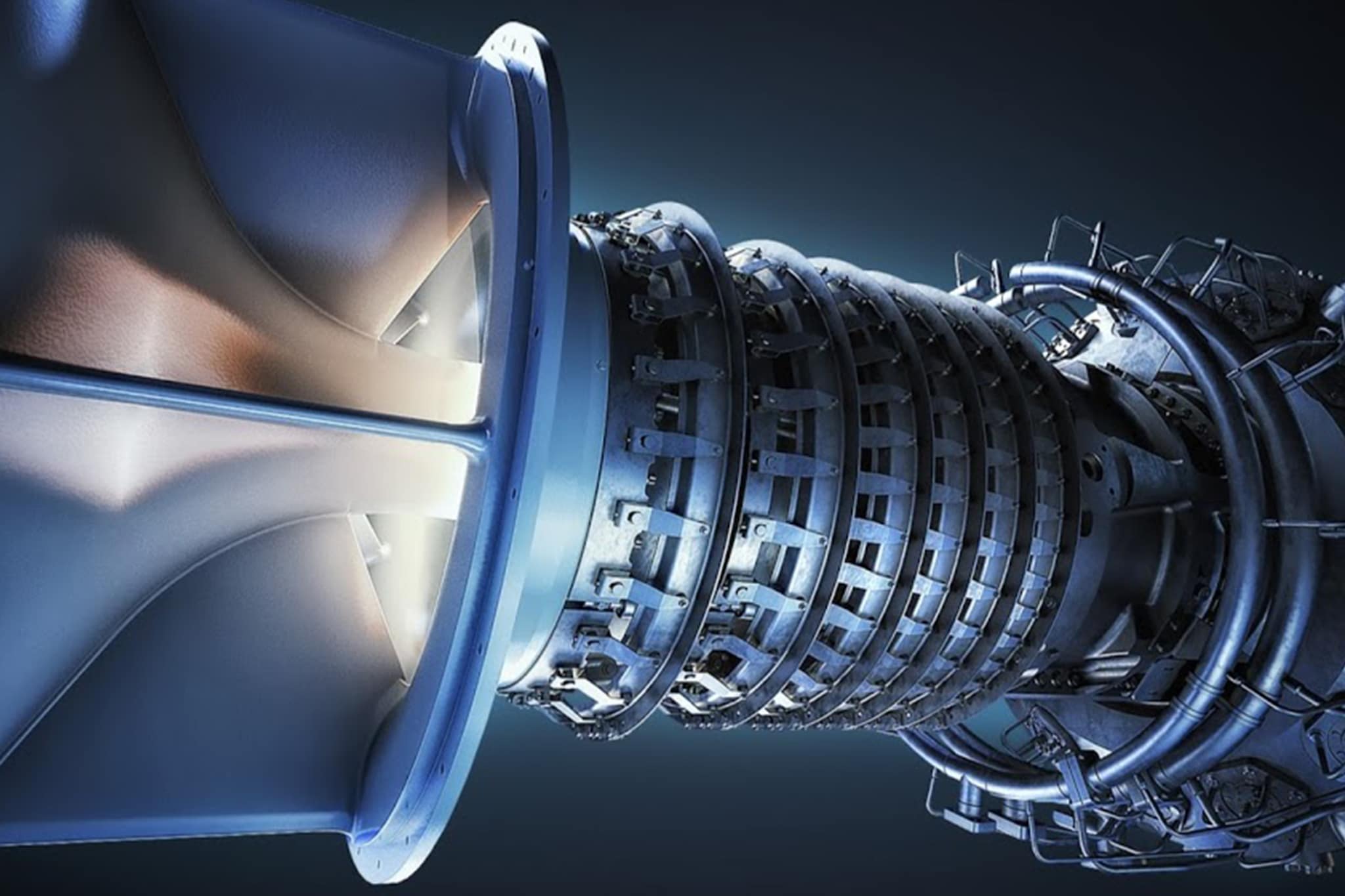

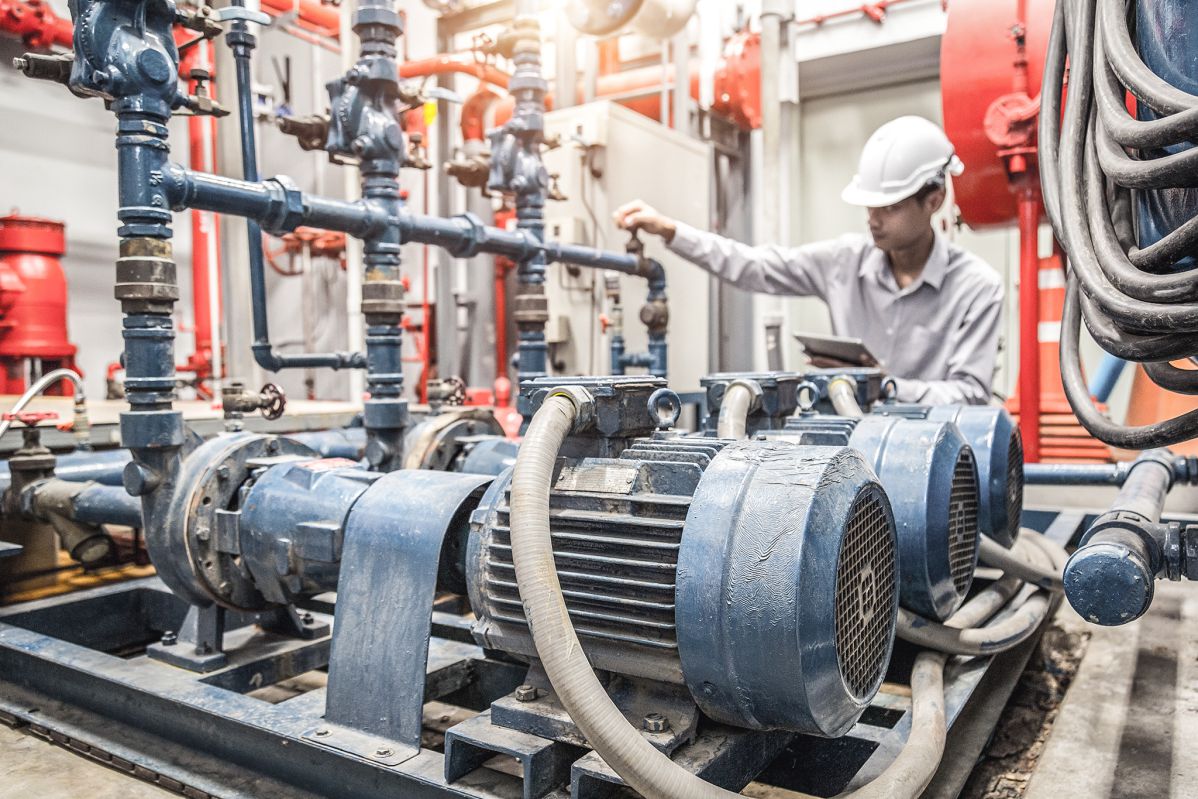

A compressor in a chemical plant in China was experiencing erratic changes in bearing temperatures. The temperatures were cycling between 75 – 90°C and the MPC levels were at 5.9 with an ISO cleanliness of 18/15/9. This threatened to shut down the plant with unplanned downtime.

Solution

Fluitec’s ESP VITA III was installed and within two days, the bearing temperatures normalized at 76°C and remained at this level consistently for more than two months. The MPC level also decreased while the ISO cleanliness rating improved significantly. This ensured that there was no unplanned downtime for the plant.

Results

- After the installation of the VITA ESP III, the bearing temperatures on the compressor became steady and no longer threatened the shutdown of the plant. The MPC levels decreased from 5.9 to 1.6 and the ISO ratings became cleaner from 18/15/9 to 15/13/10.