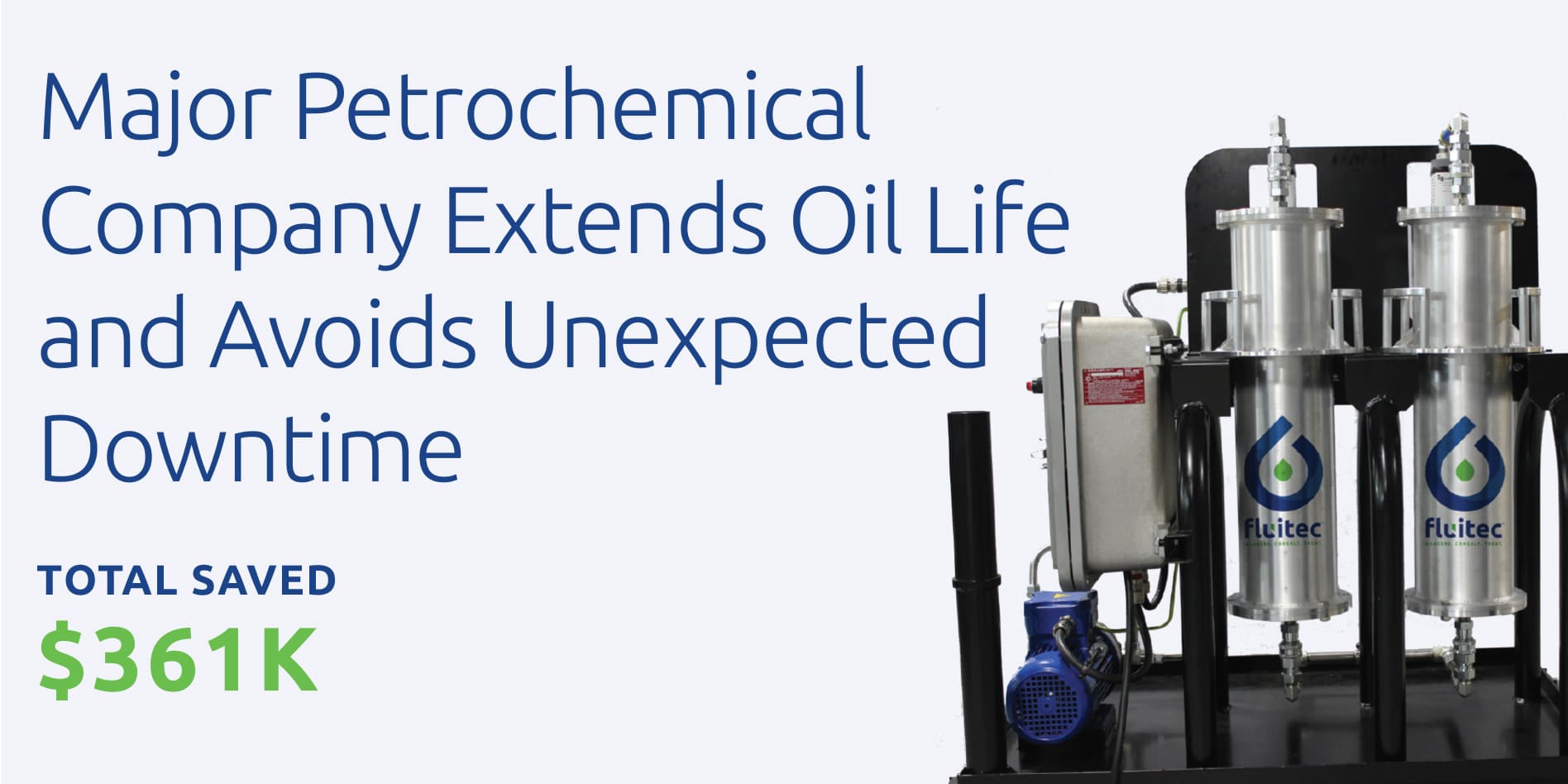

Major Petrochemical Company

Problem

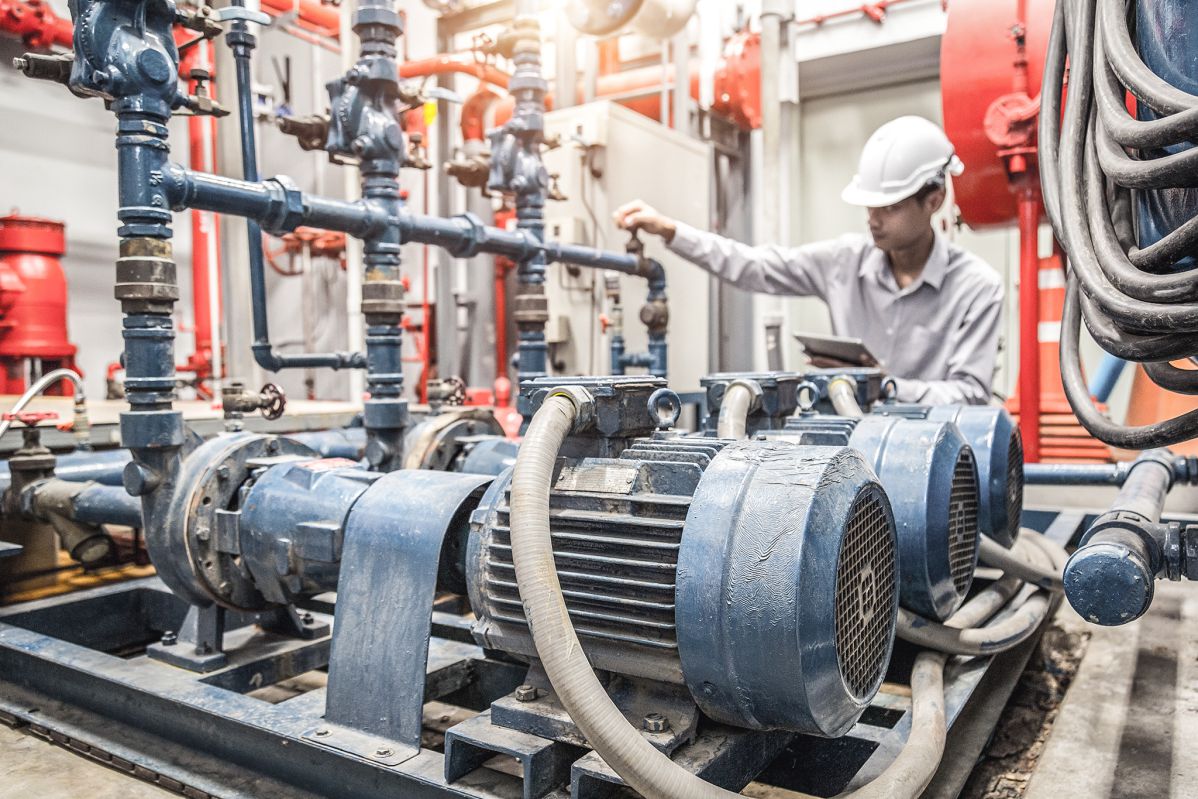

A major petrochemical company began experiencing high bearing temperatures. Upon investigation, they discovered that while the varnish potential was stable, the MPC levels were above 30. The Mitsubishi compressor was not due for an oil change for the next 12 months and the plant did not want to experience any unexpected downtime.

Solution

After consulting with Ocean Team Qatar, a Petrotec company, Fluitec’s VITA ESP III (Electrophysical Separation Process) was placed on the reservoir of the compressor system and 3% treat rate of DECON was also added to aid in the removal of these deposits.

Results

- MPC values were reduced below 5 within 4 days

- MPC values were maintained under 5 during the next few months before the oil change

- Bearing temperatures stabilized no longer threatening unexpected shutdowns

- System is varnish free

$361,000 in Cost Savings

Other Projects

Extending the oil life of a gas compressor at an Air Separation Plant

ESP and Boost VR / USA

More details