Natural Gas Pipeline

Problem

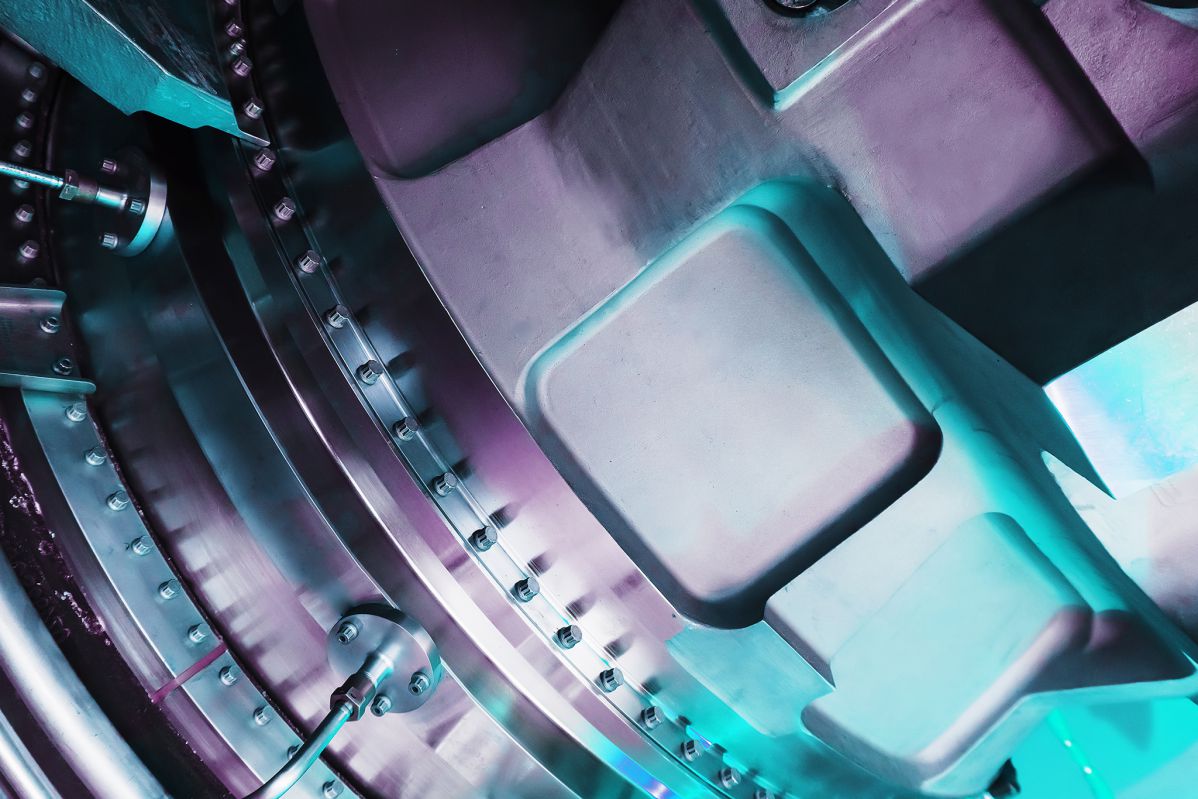

Varnish deposits and high MPC values were noticed on a Solar gas turbine used to drive a compressor on a large Natural Gas pipeline. The unit could not be shut down for an oil change as this would further compound service disruptions to the end user and lead to the reduced volumes of natural gas being supplied. These all affected the end customer’s efficiency.

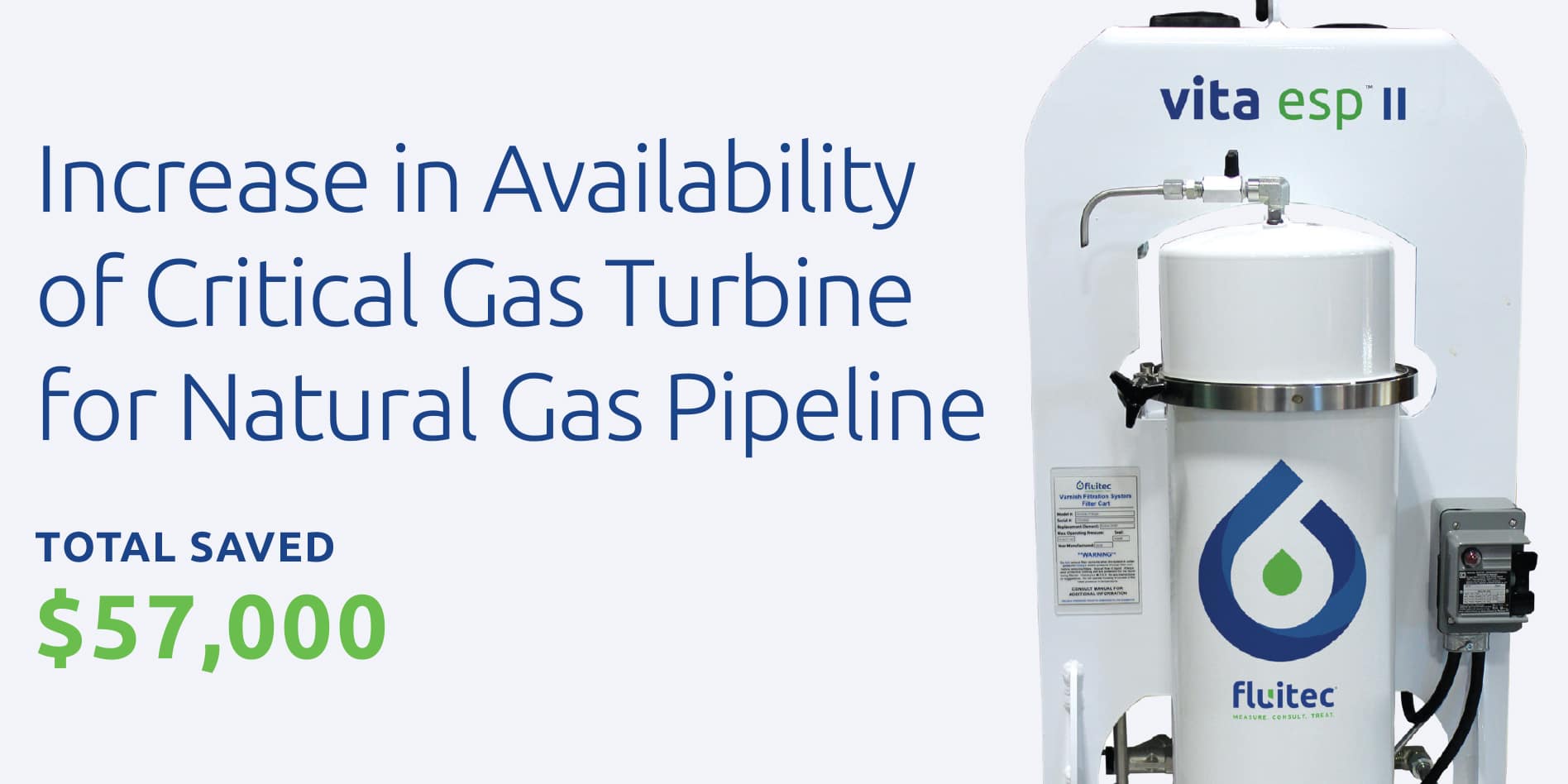

Solution

Fluitec’s ESP unit was installed and began to clean up the deposits immediately! Within four weeks the levels had normalized and these were maintained until it was convenient to shut down the equipment and change the oil.

Results

- Drastic decline in MPC (from 47 to 6) after installation of ESP unit

- MPC levels maintained the normal range between 20 -22 until the oil was changed

- Reduced critical downtime due to system deposits

$57,000 in Cost Savings

Other Projects

Extending the oil life of a gas compressor at an Air Separation Plant

ESP and Boost VR / USA

More details