About

This case-study has been developed in partnership with the Solar Impulse Foundation, who is promoting – through assessing, certifying and facilitated access to finance – the multitude of clean and profitable solutions currently available worldwide. Discover more Solar Impulse Foundation’s labelled solutions here.

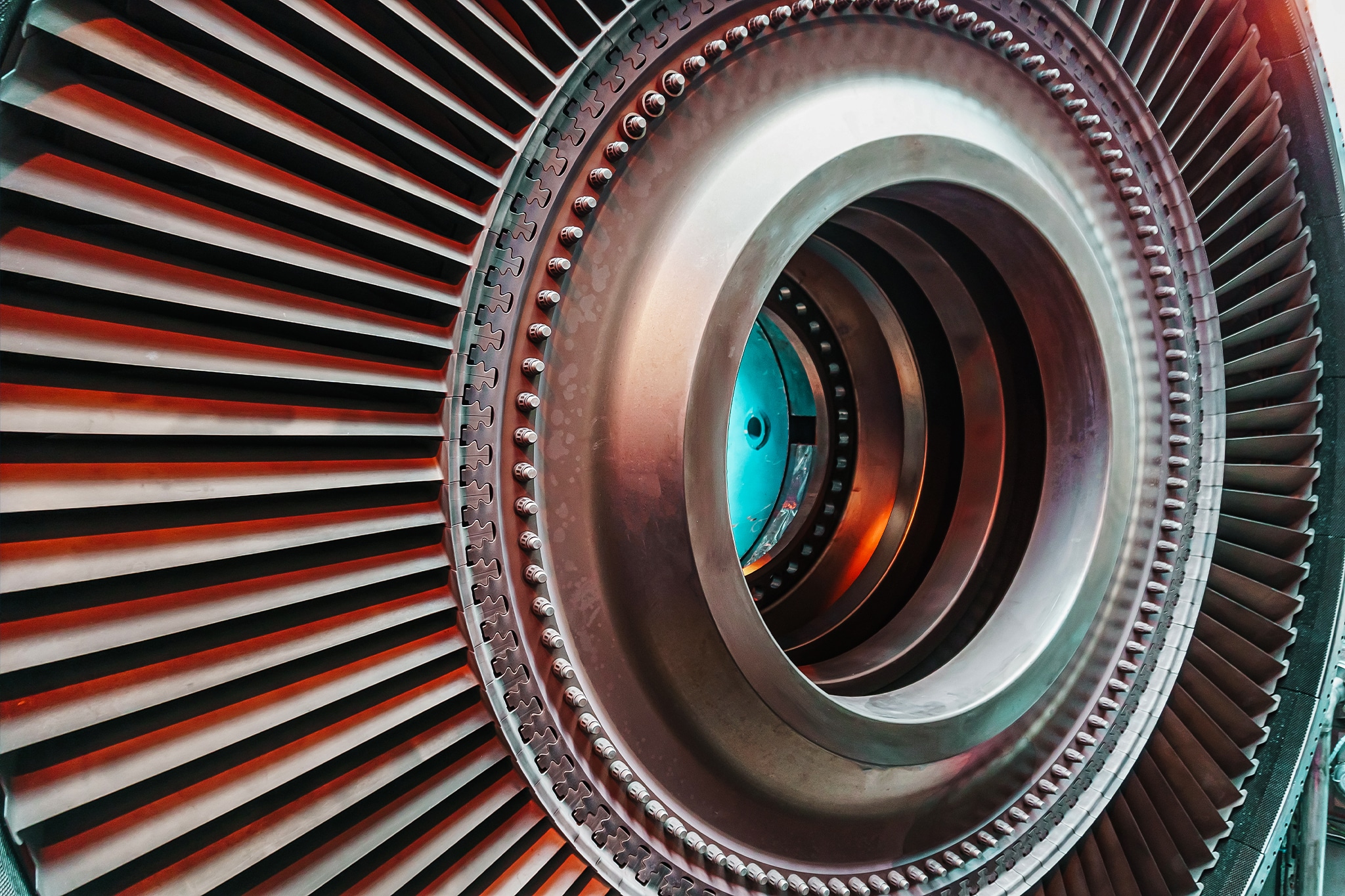

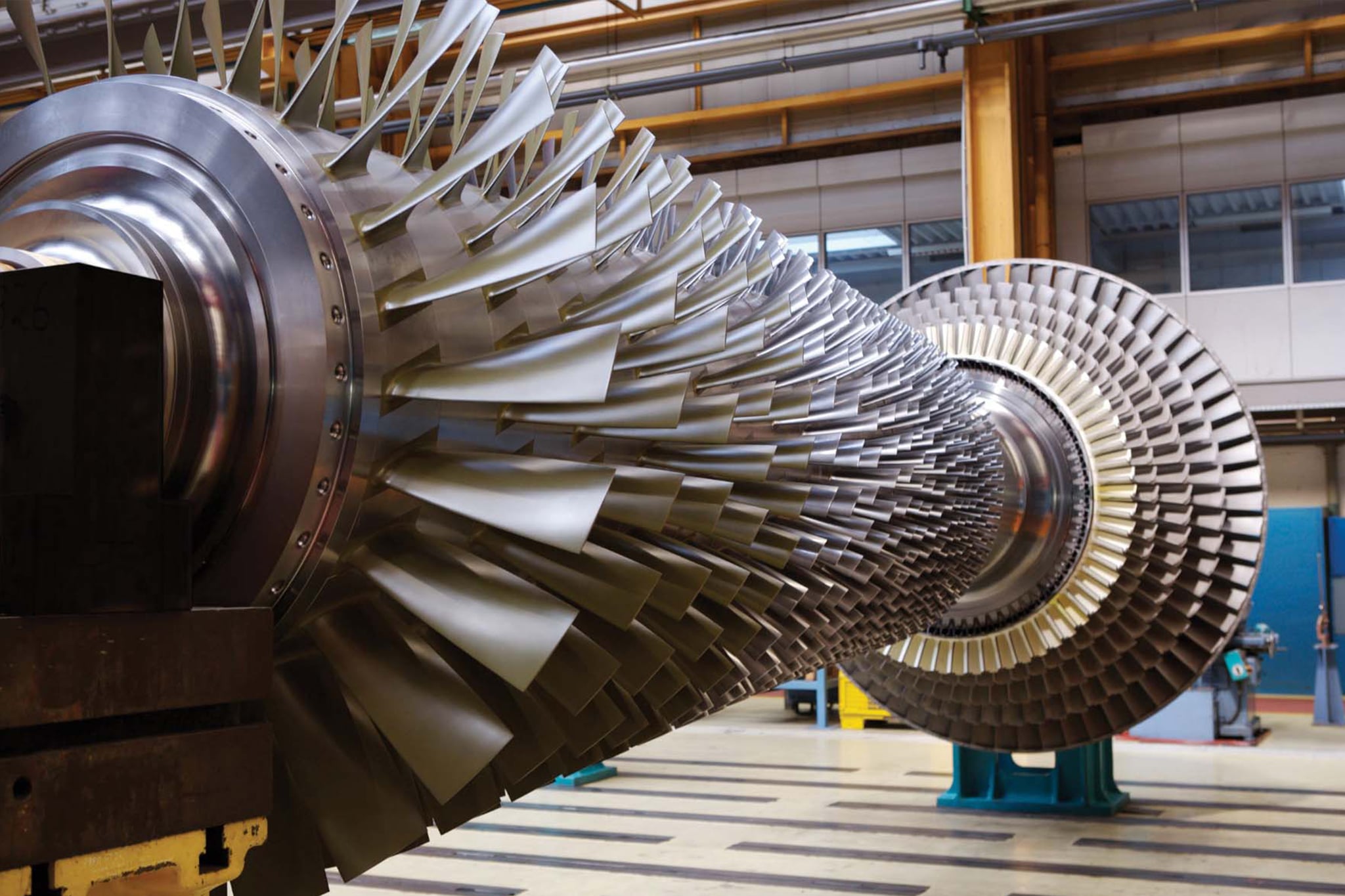

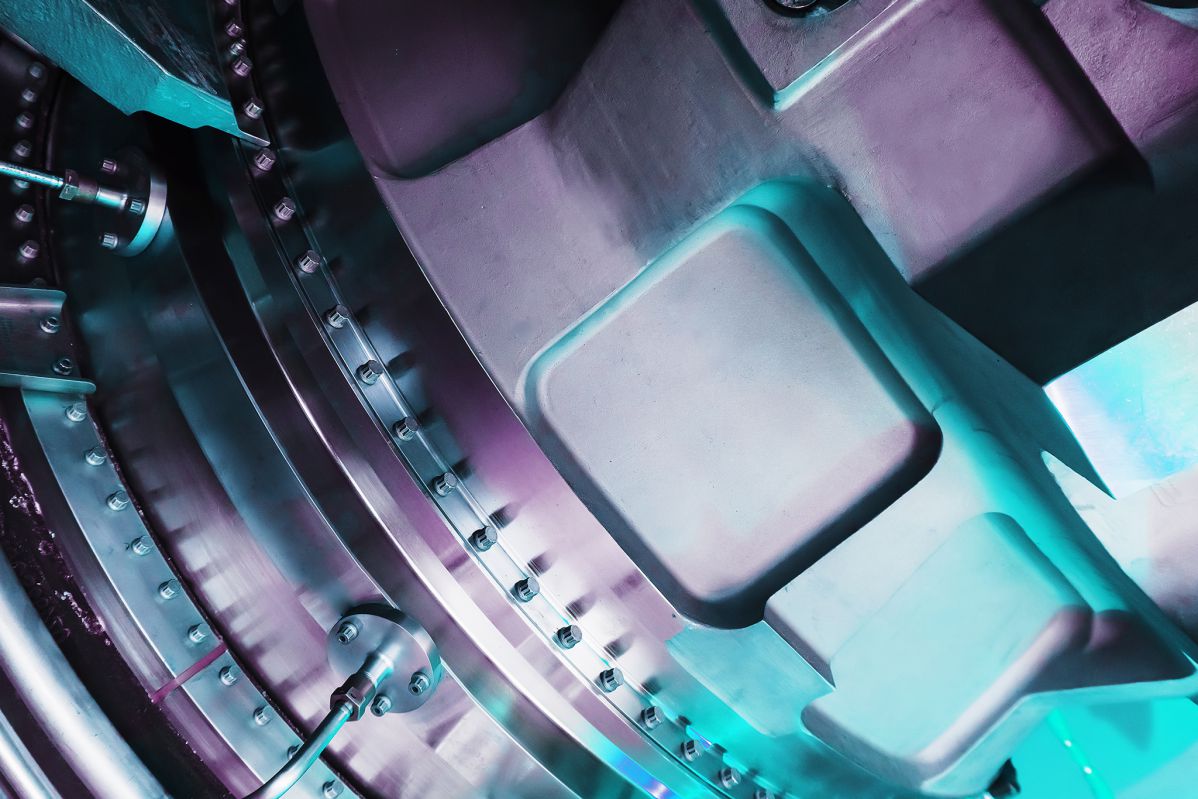

SRP (Salt River Project), a public power utility in the United States, provides reliable and affordable electricity and water to over two million people in central Arizona. As part of its commitment to sustainable operations, SRP recognized the need to address the issue of premature oil degradation in its combined-cycle power plants. Traditional oil management practices involved frequent oil changes, which not only incurred significant costs but also contributed to environmental pollution through the production, transportation, and disposal of new lubricating oil. This case study took place at SRP’s Mesquite Power plant in Arlington, Arizona. It is a 1250MW combined cycle power plant.

Solution

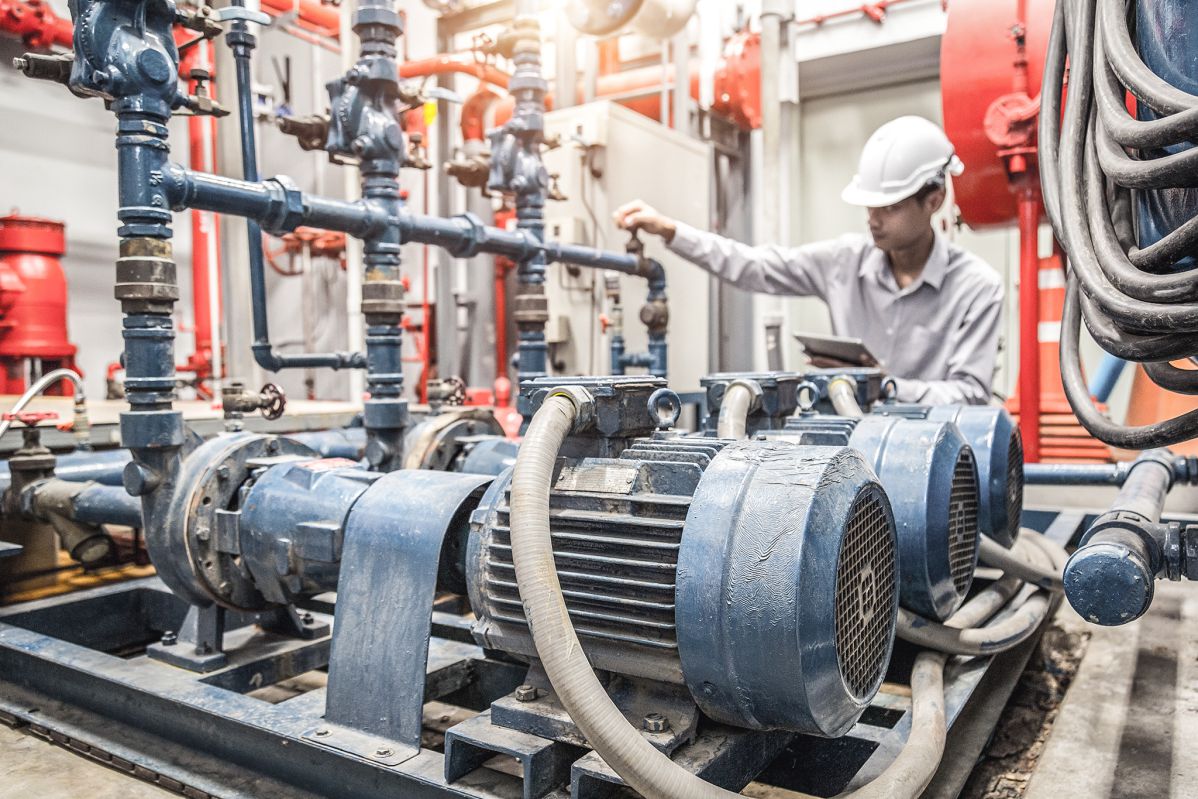

SRP partnered with Fluitec to implement the Fill4Life™ program, a comprehensive solution that enables a “fill for life” strategy for lubricants. This approach involves:

- Contaminant Removal

Fluitec’s technology filters out harmful particles, water, and other contaminants that contribute to oil degradation. - Component Replenishment

Essential additives and solubilizers are replenished to maintain the lubricant’s optimal performance and protective properties. - Continuous Monitoring

Online and offline oil analysis is conducted to monitor lubricant health and identify potential issues before they escalate.

By continuously maintaining and optimizing the condition of the lubricant, the program eliminates the need for frequent oil changes, extending the lifespan of lubricants and reducing waste.

Results

The implementation of the program has yielded substantial financial benefits for SRP’s Mesquite Power. By optimizing oil life and preventing associated costs with oil changes, Mesquite Power realizes over $275,000 per year in OPEX savings (Operating Expenses) and over 150 tons per year in CO2e emissions. Furthermore, less human interaction with their turbine oil translates to a safer working environment for their employees. Investment costs are lower than the cost of one oil change, so savings are realized immediately.